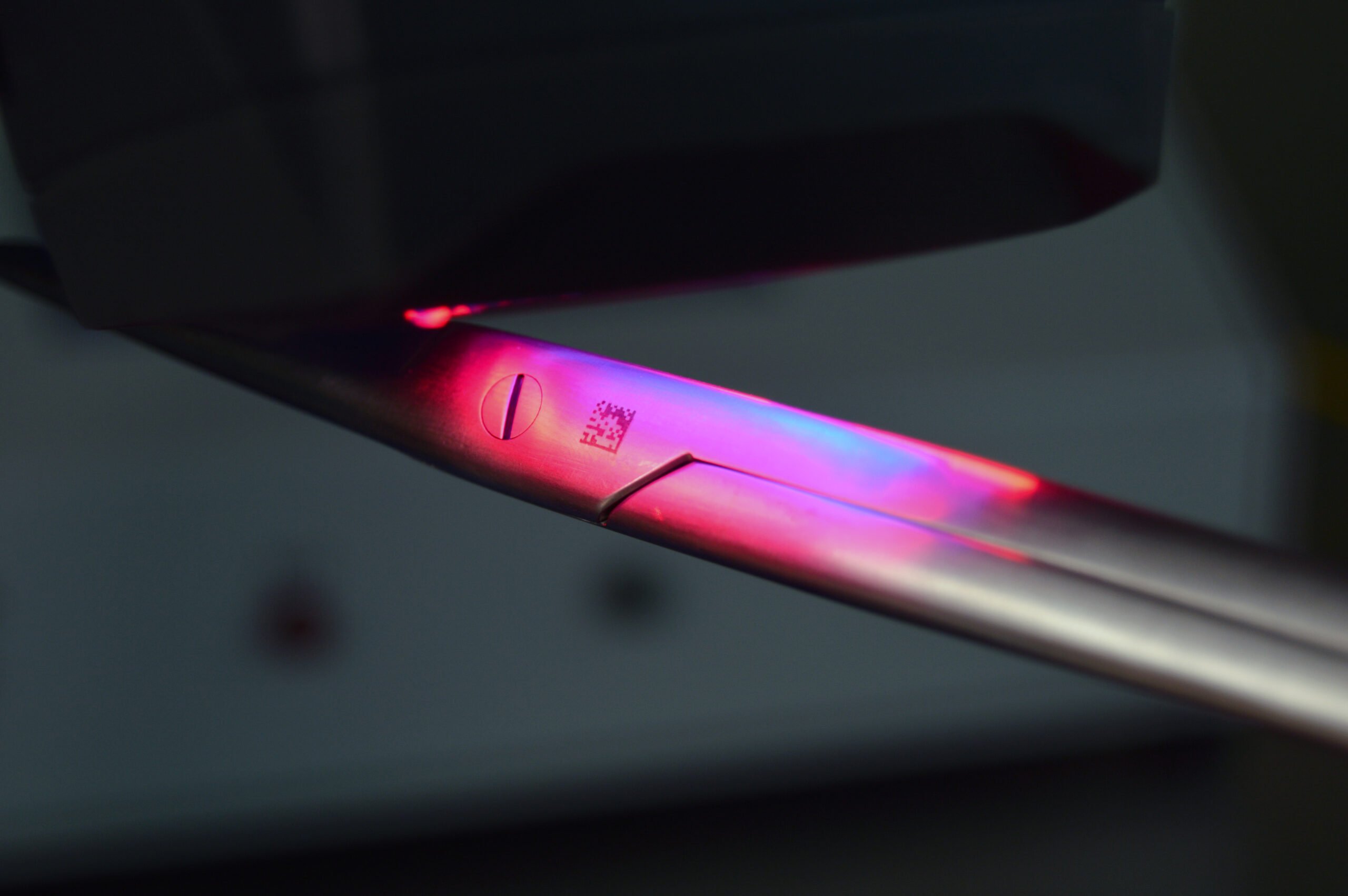

Sterile processing departments are increasingly taking on more responsibility for patient safety. In May 2021, the FDA established the unique device identification system which now links surgical instruments directly to the patient. A high-quality instrument tracking system is more important now than ever.

Today, it is still common for a sterile processing department to conduct tracking to the tray level only, increasing the risk of a surgical site infection and not meeting these new regulatory standards. At Censis, we believe that instrument-level tracking should be the best practice for all sterile processing departments. Beyond meeting FDA regulations, tracking instruments to the instrument level has significant safety and financial benefits. Here are the top three reasons you should be tracking instruments to the instrument level:

1. Complete Visibility of Your Assets Throughout the Entire Perioperative Loop

The traceability of each asset manages the risk of high-cost incidents like lost instruments or patient complications from faulty or contaminated assets. By tracking instruments down to the instrument level, your team can quickly identify which specific instrument is at fault for an infection or outbreak. Knowing the location and history of each unique instrument in an instant gives your team complete transparency throughout the entire perioperative loop.

2. Manage Risk by Covering Your Bases

The financial impact of negative patient outcomes due to surgical asset-related incidents outweighs the upfront costs of implementing an instrument tracking system. Without instrument-level tracking, your team risks liability for patient incidents, with exorbitant costs in the case of fault. With an instrument-level tracking system like CensiTrac Advanced, your team has access to real-time reports like case information, current asset location, individual instrument tracking reports, and more to ensure all your bases are covered in the event of an incident. The implementation time and upfront costs are well worth the long-term investment in patient safety.

3. No More O.R. Slow Downs

By tracking to the instrument level, tray assembly becomes faster and more accurate which impacts O.R. turnaround time. If a tray has the wrong assets, CensiTrac Advanced will alert the technician with visual and audible cues so they know which specific instrument is providing a problem and how to resolve the issue before moving on. Specific integrity tests and checks and usage tracking for serviceable instrument guarantees, special assembly instructions, approved substitutions, and critical assets required for a tray to proceed to sterilization are more detailed and accurate when scanning each instrument into its specific tray.

Still not convinced to make the switch to instrument level tracking? Our previous blog dives deeper into the differences between tray tracking and instrument level tracking. Contact our team to learn more about how CensiTrac Advanced makes labeling and tracking instruments a simple process with serious benefits.